Additional HBR BFO Circuits

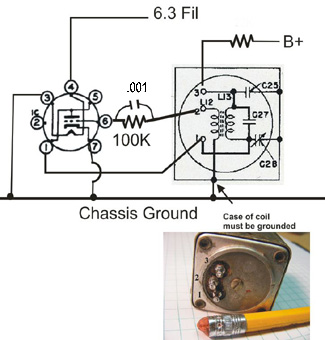

Here

is a schematic of Ian Wilson's BFO using the Command Set series coil in

a

test circuit.

Ian

Wilson

"This

worked over supply voltages from 90 to 250 volts. The tuning range is

about

83 to 86.2 kHz. You might want to follow Breck's modification to disconnect

the internal variable

capacitor to get a bit more range." "Note the the connection

to the can is necessary. For my lash-up

I have a solder tag under one of the screws holding the base to the can."

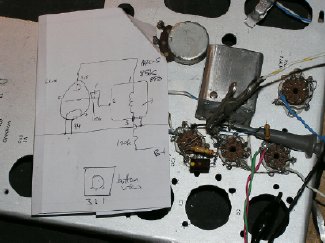

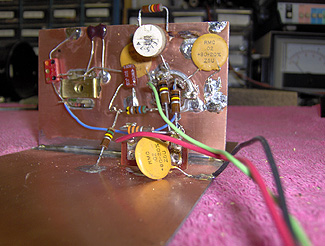

The

BFO circuit shown below is for the HBR-16 using a 6BH6 and was

constructed by Pete WB2JWU

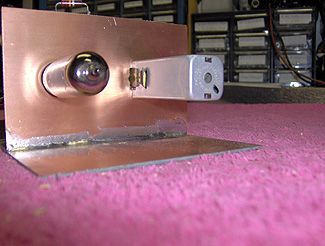

photo

WB2JWU

Pete was unable to obtain a center

tapped coil and changed the 6BH6 circuit to a Colpitts.

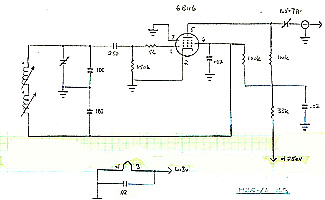

Here

is the original HBR-16 6BH6 circuit. Note the tapped coil.

Notice that the HBR-16 uses a variable capacitor C9(1.7-7 pF trimmer to

control injection.

On the HBR 14 W6TC used a "gimmick" capacitor. On the HBR-14

that I built I later changed the gimmick

to a small piston cap which can be seen on the previous pages.

Photo

WB2JWU

Note

the use of copper clad PC board material for Pete's bread board. The board

is

easy

to solder and makes it easy to establish ground connections and to mount

components.

Photo

from QRP Builder WA4MNT

The

builder might consider using copper clad PC board material for his BFO

enclosure.

"QRP

Builder" has a nice article on constructing a chassis using PC material.

http://qrpbuilder.com/