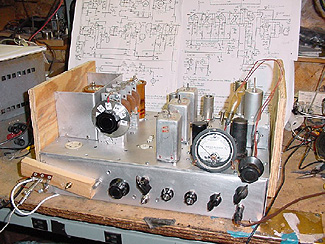

You have to start somewhere but don't delay construction

just to find one major

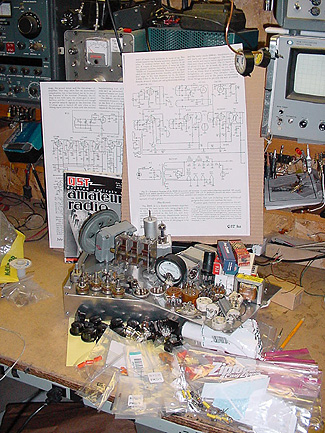

component. Note the enlarged schematics mounted on cardboard,

the enlarged schematic

is a big help during construction, easy to read and you can make pencil

notes beside the circuits.

Don't

forget to update your schematic with the QST feedback changes.

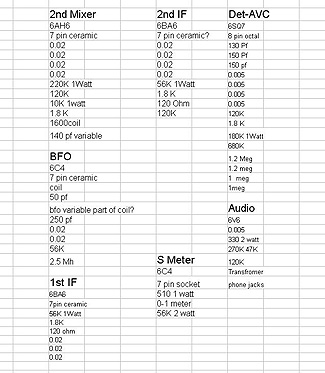

An organized parts list is a must.

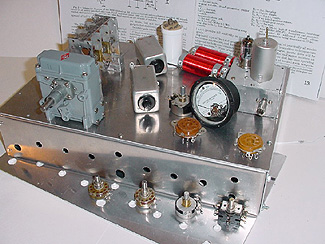

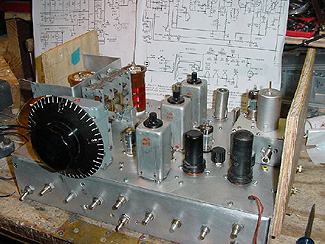

Layout your parts, note that the BFO circuit

housing location will determine where

other components will be mounted. Resolve the BFO circuit and housing

first. Shown is

a "Fred Byers K3IWK Chassis"

Byers Chassis

kits: http://www.k3iwk.net/

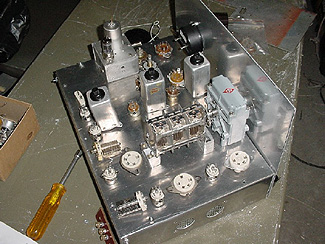

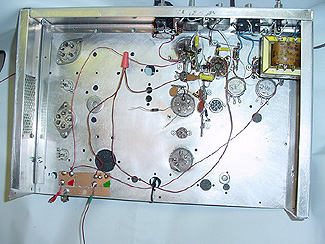

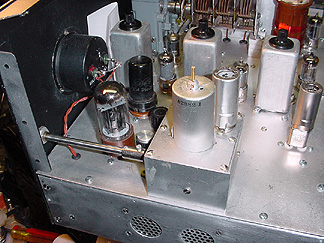

In this photo the BFO is finished, the 1600 Kcs coils are ready

and the variable capacitor mounts are finished. Note that the top plate on the Byers chassis can be

removed for mounting of parts and it makes it easy for initial wiring.

BFO

enclosure is on the left. Note that the power supply

is missing. Do your self a favor and use an external power supply

that is separate from the main

chassis. Less hum problems, heat etc.

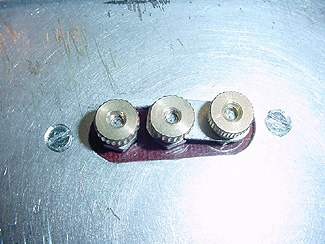

The Byers chassis is a kit. You drill the holes and assemble.

Do

you self another favor and order some decent hardware. Machine

nuts

with built in lock washers are handy for those tight places. Also known

as Kep

Nuts or K-lock nuts.

I

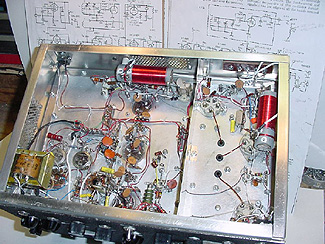

built the original HBR-14 receiver without any major modifications.

Don't listen to those experts, leave the HBR-14 circuit alone and you

will have

a working receiver.

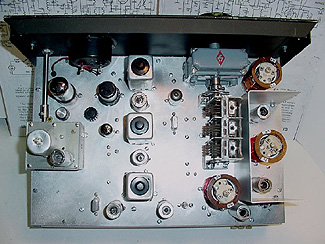

Build the receiver "backwards" - - - start with the audio section first

and you will be able to use it to test the other sections. Be sure and include the

S- meter circuit as it will come in handy during testing and alignment.

Note the temporary power distribution board mounted at bottom left.

Neat

thing about an HBR project like this is you will fabricate lot of odds

and

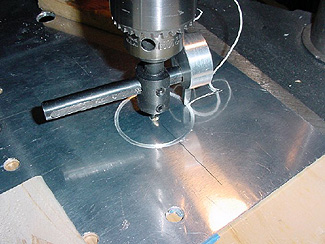

ends. Shown is the antenna connector.

During

progress testing I tested the receiver without the front RF stage.

The antenna was fed direct into the mixer and the result was excellent

sensitivity.

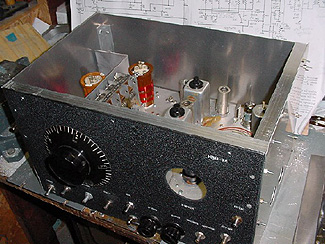

Note the variable capacitor has

a direct drive knob with a rough scale attached.

This aids in initial band spread testing and you can zip back and forth

from one end of

the band to the other.

I got very distracted at this time

as I had a working receiver and spent a lot of time

cruising the bands. The simple knob and direct drive on the variable capicator

allowed me

to quickly sweep the band to look for signals.

BTW watch out for that S-meter circuit

it can shock the piss out you.

I choose

the older HRO PW knob and drive assembly. The dial has plenty of

band spread and no calibration is necessary, just make up a chart after

the receiver is finished.

The plywood boards mounted on the sides were taken off for final assembly

but protected the

components on the upper part of the chassis during contruction and testing.

The all important BFO circuit is mounted and an extension shaft is utilized.

A lot of builders will put off the BFO circuit till the last but that is a mistake.

Resolve the BFO issue at the beginning.

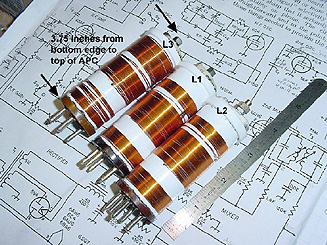

When

considering a housing for the receiver make sure you have vertical

clearance for the 160 meter coils. These extra long coils were fabricated

on homemade

PVC coil forms mounted on cut off tube bases salvaged from bad tubes.

In

order to keep the weight down and to have room for the 160 meter

coils I just made a cabinet by bolting on aluminun sides to the Byers

chassis and then adding

a hinged top. Note the use of aluminum angle on the tops and

in the corners.

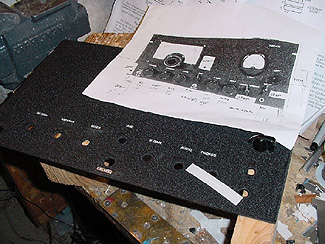

Black wrinkle paint and simple "Brother Labels" covered with clear finger nail polish.

Note the cooling inlets covered with screen on the chassis sides and

rear, much neater than drilling a bunch of holes.

A display at the Gilbert MRCA, emphasis was on the junk command set on the

right being used for something useful.